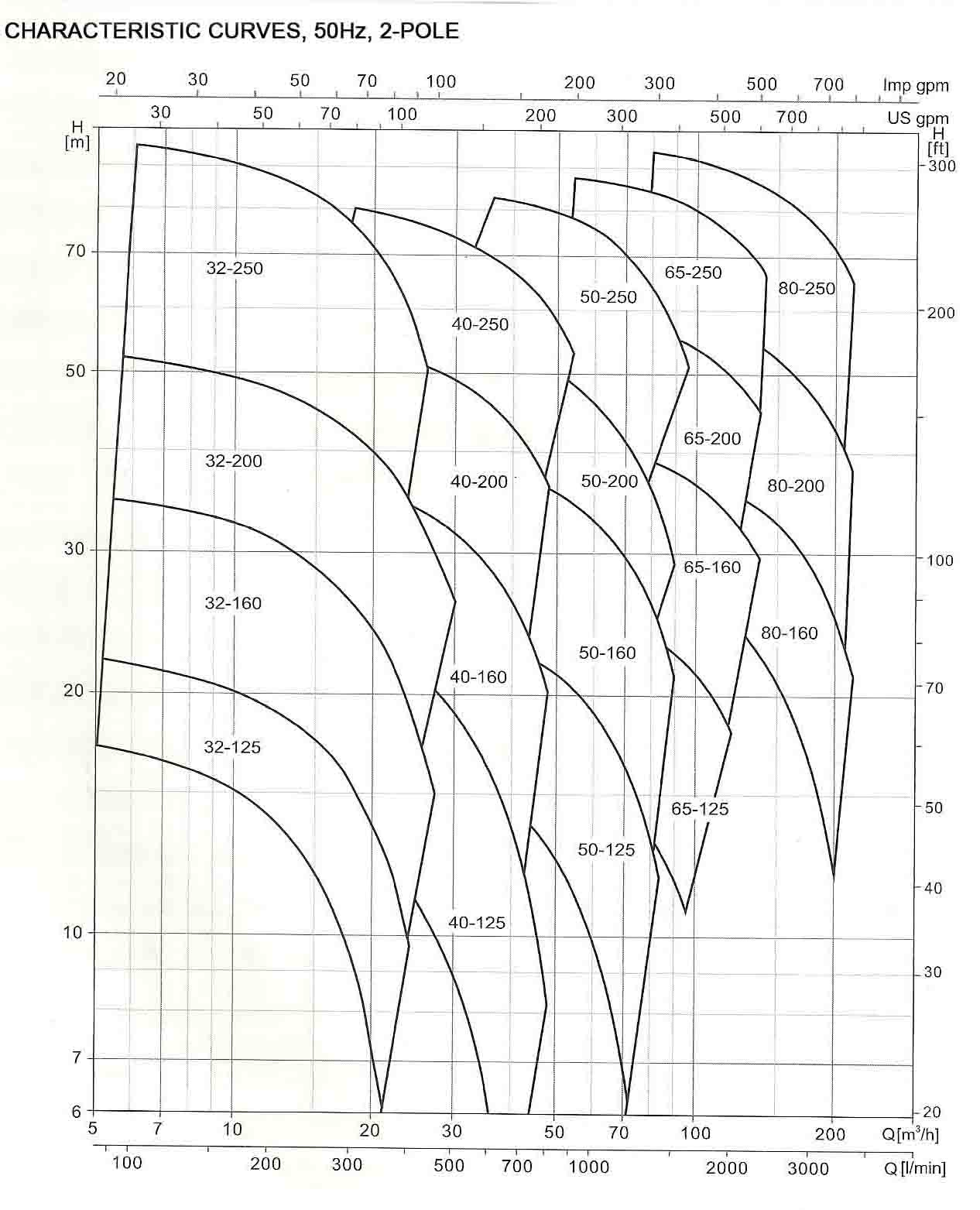

STANDARD CENTRIFUGAL PUMPS (EN733-DIN24255)

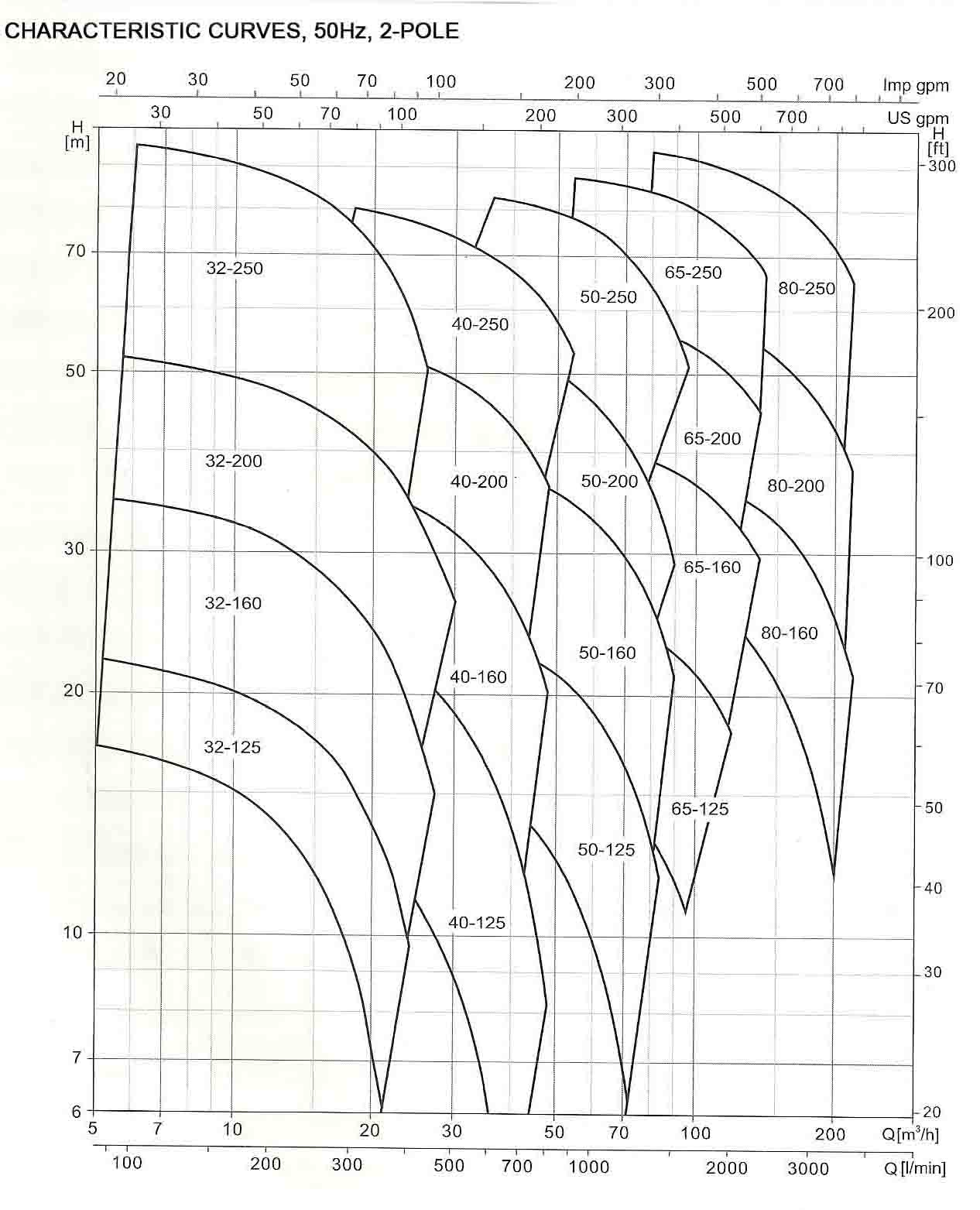

RANGE OF PERFORMANCE

8Flow rate up to 138 m3/h

8Head up to 99m

LIMITS OF USE

8Liquid temperature up to +60℃

8Environment temperature up to +40℃

8Max. operating pressure: 12 bar

INSTALLATION AND USE

8These pumps are suitable for handling clean water without abrasive particles and liquids that are chemically non-aggressive to the pump components. Reliable, economical and simple to use, they are suitable for domestic use and in particular for distributing water in combination with small pressure sets, for irrigating gardens. The pumps must be installed in a covered area, protected against the inclement weather.

8They are mainly used for water supply & irrigation, air conditioning system, boosting, fire fighting and circulating or transferring in civil, industrial and agricultural applications.

MOTOR

8Two –pole induction motor (n=2850rpm)

8Three-phase asynchronous, squirrel cage rotor

8Closed construction, external ventilation

8Insulation Class B/F

8Protection grade IP55

8Overload protection

MATERIALS

8Pump body: Cast iron

8Pump cover: Cast iron

8Impeller: Cast iron or Stainless Steel

8Shaft: Stainless Steel

8Mechanical seal: SiC-SiC, Graphite-Ceramics

8Bearing: NSK, C&U, or local quality.

WARRANTY: 1 YEAR (according to our general sales conditions)

|

MODEL |

POWER |

|

Q=DELIVERY |

|

l/min |

0 |

100 |

150 |

250 |

300 |

400 |

450 |

600 |

700 |

800 |

900 |

1200 |

1400 |

1500 |

1800 |

2000 |

|

KW |

HP |

m3/h |

0 |

6 |

9 |

15 |

18 |

24 |

27 |

36 |

42 |

48 |

54 |

72 |

84 |

90 |

108 |

120 |

|

32-125/0.75 |

0.75 |

1 |

H(m) |

17.5 |

16.7 |

15 |

12 |

9 |

|

|

|

|

|

|

|

|

|

|

|

|

32-125/1.1 |

1.1 |

1.5 |

22 |

21 |

19.7 |

16.5 |

14.5 |

9 |

|

|

|

|

|

|

|

|

|

|

|

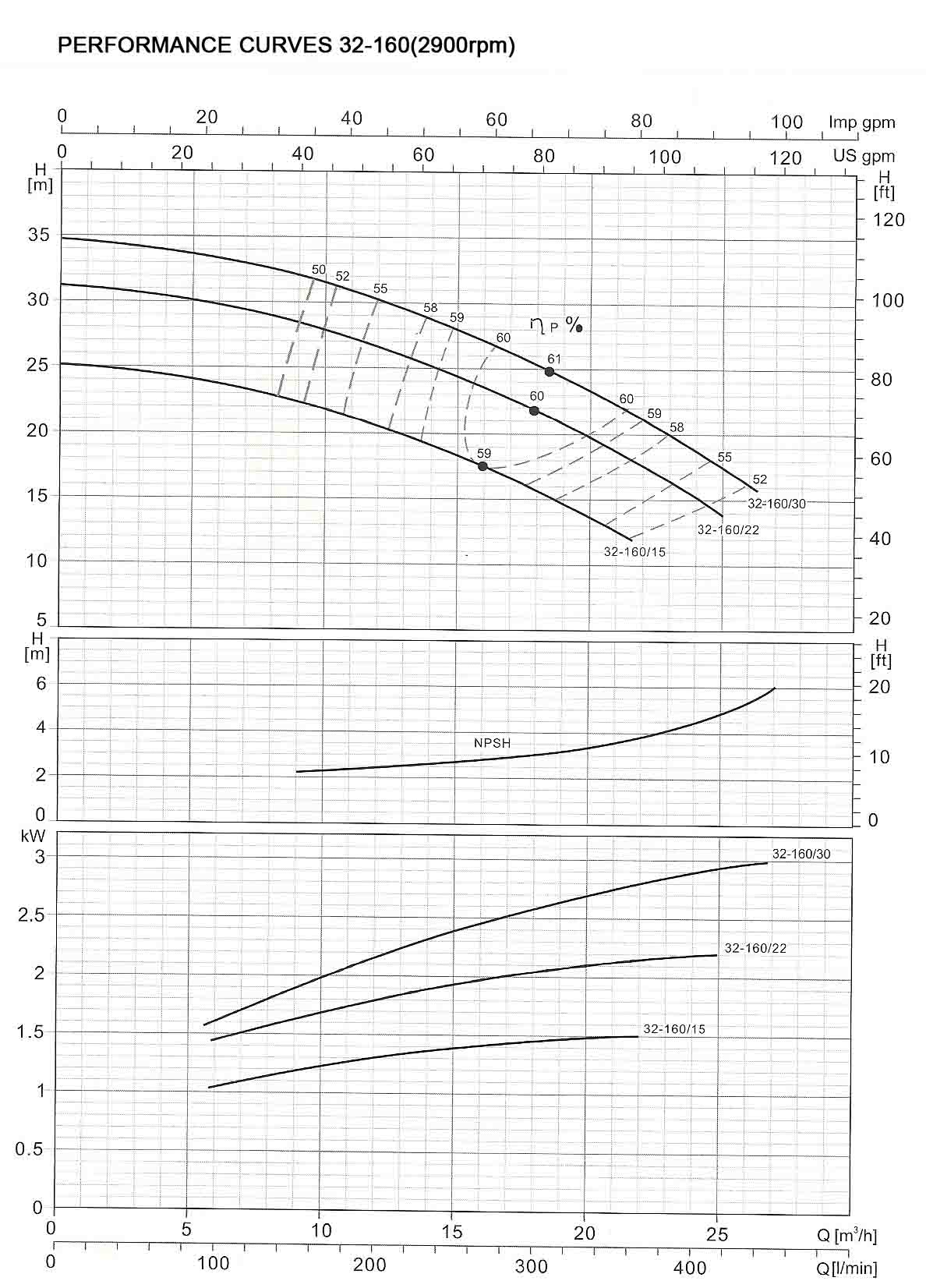

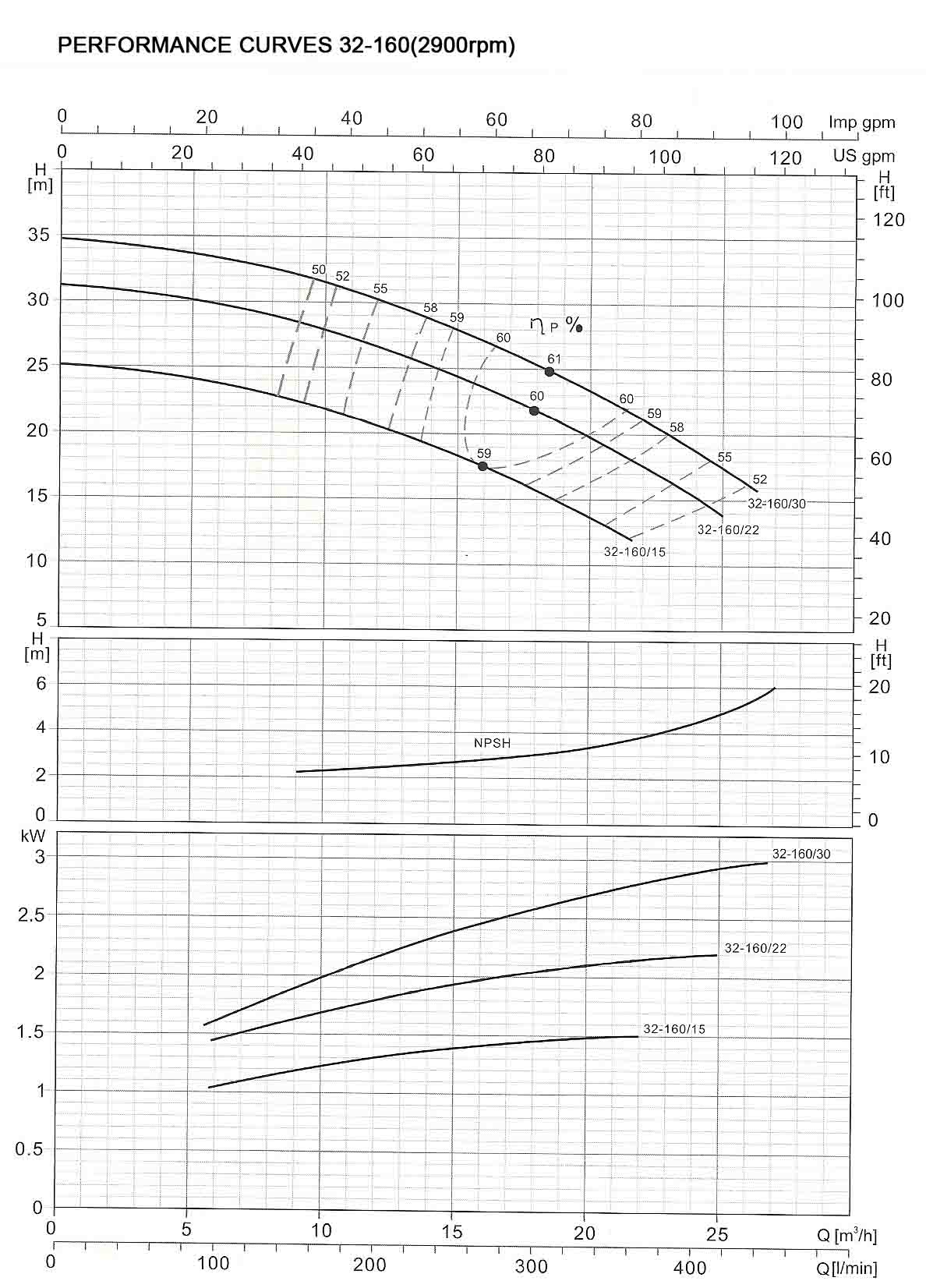

32-160/1.5 |

1.5 |

2.0 |

25.4 |

23.7 |

22.5 |

18.5 |

15.8 |

|

|

|

|

|

|

|

|

|

|

|

|

32-160/2.2 |

2.2 |

3.0 |

31 |

29.6 |

28.5 |

24.5 |

22 |

15 |

|

|

|

|

|

|

|

|

|

|

|

32-160/3.0 |

3.0 |

4.0 |

35 |

34.3 |

34 |

28 |

25.5 |

19 |

15 |

|

|

|

|

|

|

|

|

|

|

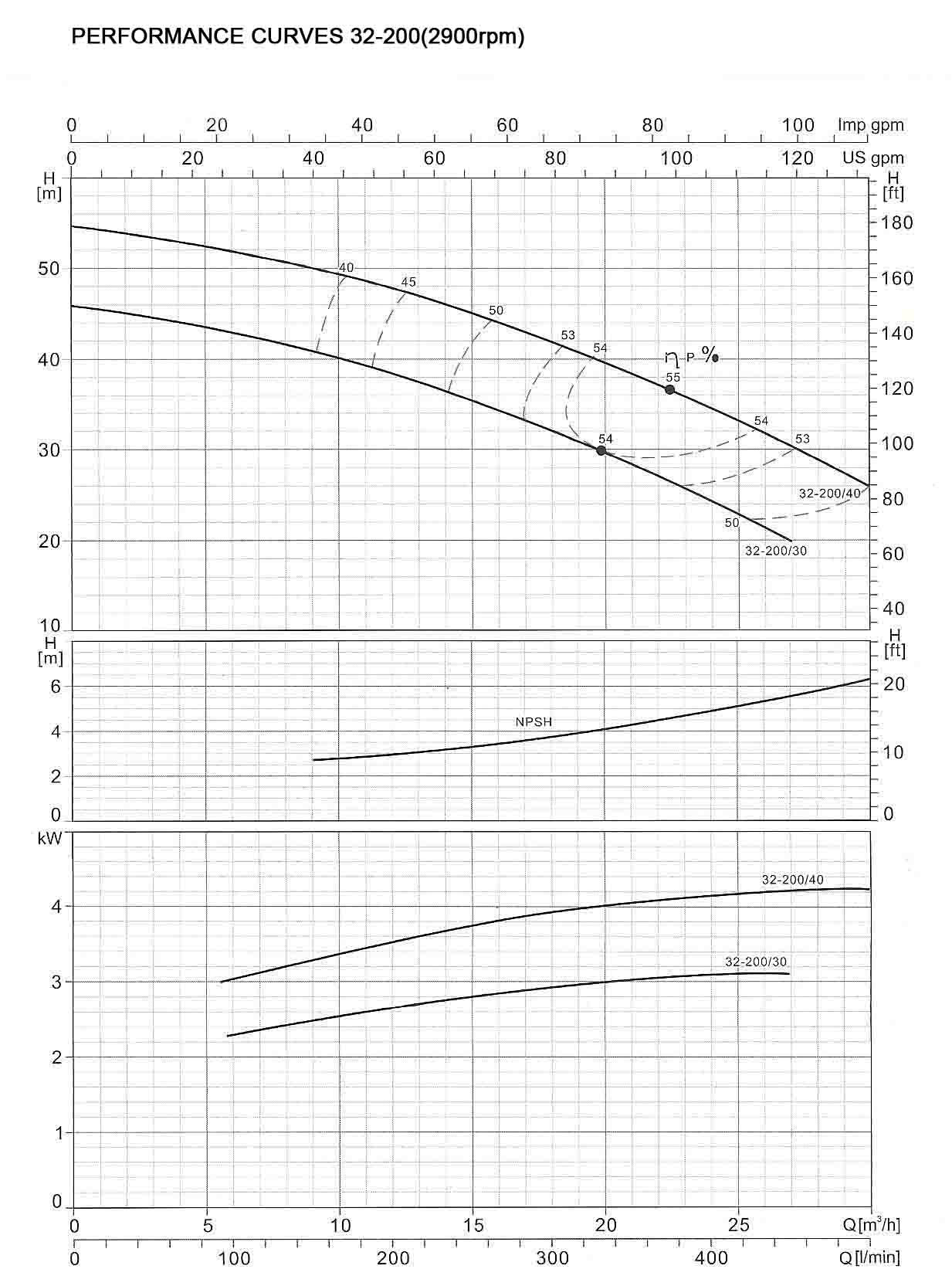

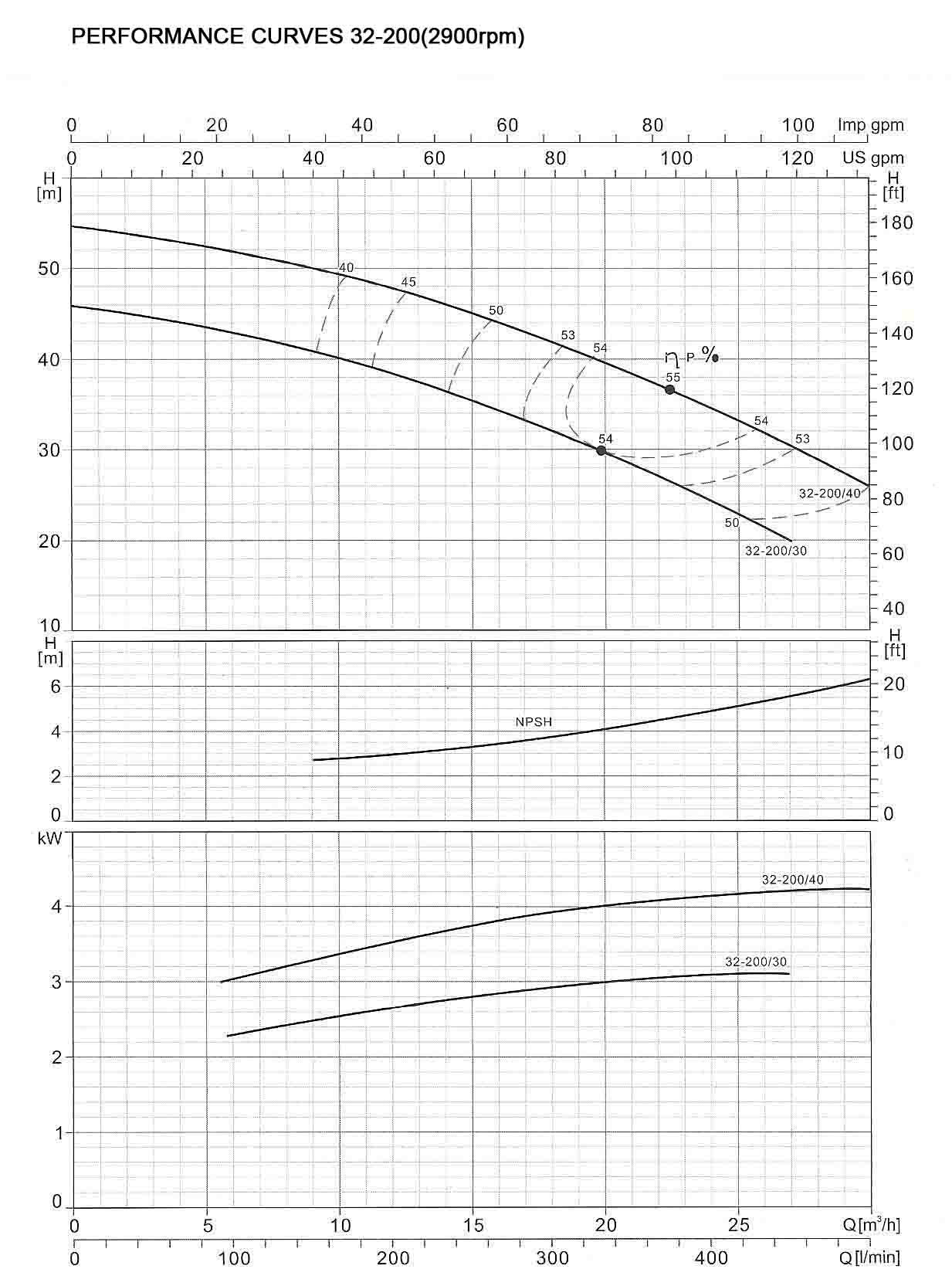

32-200/3.0 |

3.0 |

4.0 |

44.2 |

43 |

39.8 |

35.2 |

32.2 |

24.6 |

19.8 |

|

|

|

|

|

|

|

|

|

|

32-200/4.0 |

4.0 |

5.5 |

54.5 |

52 |

50 |

45.5 |

41.9 |

35 |

30.3 |

|

|

|

|

|

|

|

|

|

|

32-250/5.5 |

5.5 |

7.5 |

79.5 |

74.7 |

71.8 |

63 |

56 |

37.5 |

|

|

|

|

|

|

|

|

|

|

|

32-250/7.5 |

7.5 |

10 |

99.5 |

95 |

91.8 |

83 |

76 |

57.8 |

|

|

|

|

|

|

|

|

|

|

|

40-125/1.5 |

1.5 |

2.0 |

18.1 |

|

|

|

17 |

15 |

13.9 |

9.6 |

6 |

|

|

|

|

|

|

|

|

40-125/2.2 |

2.2 |

3.0 |

24.5 |

|

|

|

23.2 |

21.5 |

20.2 |

16 |

13 |

8.3 |

|

|

|

|

|

|

|

40-160/3.0 |

3.0 |

4.0 |

31.8 |

|

|

|

29.5 |

27.5 |

26.3 |

21.5 |

17.5 |

|

|

|

|

|

|

|

|

40-160/4.0 |

4.0 |

5.5 |

38 |

|

|

|

36 |

34 |

33 |

28.5 |

25 |

20.1 |

|

|

|

|

|

|

|

40-200/5.5 |

5.5 |

7.5 |

46 |

|

|

|

43.8 |

41.3 |

40.1 |

35 |

30 |

|

|

|

|

|

|

|

|

40-200/7.5 |

7.5 |

10 |

57 |

|

|

|

53.6 |

51.5 |

50 |

45 |

41 |

36.5 |

|

|

|

|

|

|

|

50-125/3.0 |

3.0 |

4.0 |

20 |

|

|

|

|

|

|

18.8 |

18 |

17 |

15.6 |

11 |

|

|

|

|

|

50-125/4.0 |

4.0 |

5.5 |

24 |

|

|

|

|

|

|

23.1 |

23 |

21.5 |

20.3 |

15.8 |

11.8 |

|

|

|

|

50-160/5.5 |

5.5 |

7.5 |

32 |

|

|

|

|

|

|

30.6 |

30 |

28 |

26.6 |

20.5 |

14.8 |

|

|

|

|

50-160/7.5 |

7.5 |

10 |

40 |

|

|

|

|

|

|

38 |

37 |

36 |

34.4 |

29 |

24 |

21 |

|

|

|

65-125/4.0 |

4.0 |

5.5 |

19 |

|

|

|

|

|

|

|

|

17.3 |

16.8 |

14.5 |

13 |

11.8 |

|

|

|

65-125/5.5 |

5.5 |

7.5 |

23 |

|

|

|

|

|

|

|

|

21.3 |

20.9 |

19 |

17.5 |

16.7 |

13.7 |

|

|

65-125/7.5 |

7.5 |

10 |

27 |

|

|

|

|

|

|

|

|

26 |

25.6 |

24.5 |

23 |

22.5 |

20 |

18 |

zmp

zmp

zmp

zmp